Stacja krystalizacji NIKA/Znamienka 2016

Projekt techniczny i dostawa urządzeń do krystalizacji i cukrzycy zarodowej dla cukrowni NIKA i Znamienka

БОЛЕЕ

Oficjalny przedstawiciel

PCM jest oficjalnym przedstawicielem wielu firm dostarczających urządzenia do przemysłu cukrowniczego na cały świat

БОЛЕЕ

Polimex Cekop Moder

Projektant instalacji przemysłowych dla wszystkich etapów procesu technologicznego

БОЛЕЕ

Przemysł cukrowniczy

Wykonujemy zarówno pojedyńcze maszyny, urządzenia, jak również kompletne obiekty, modernizacje

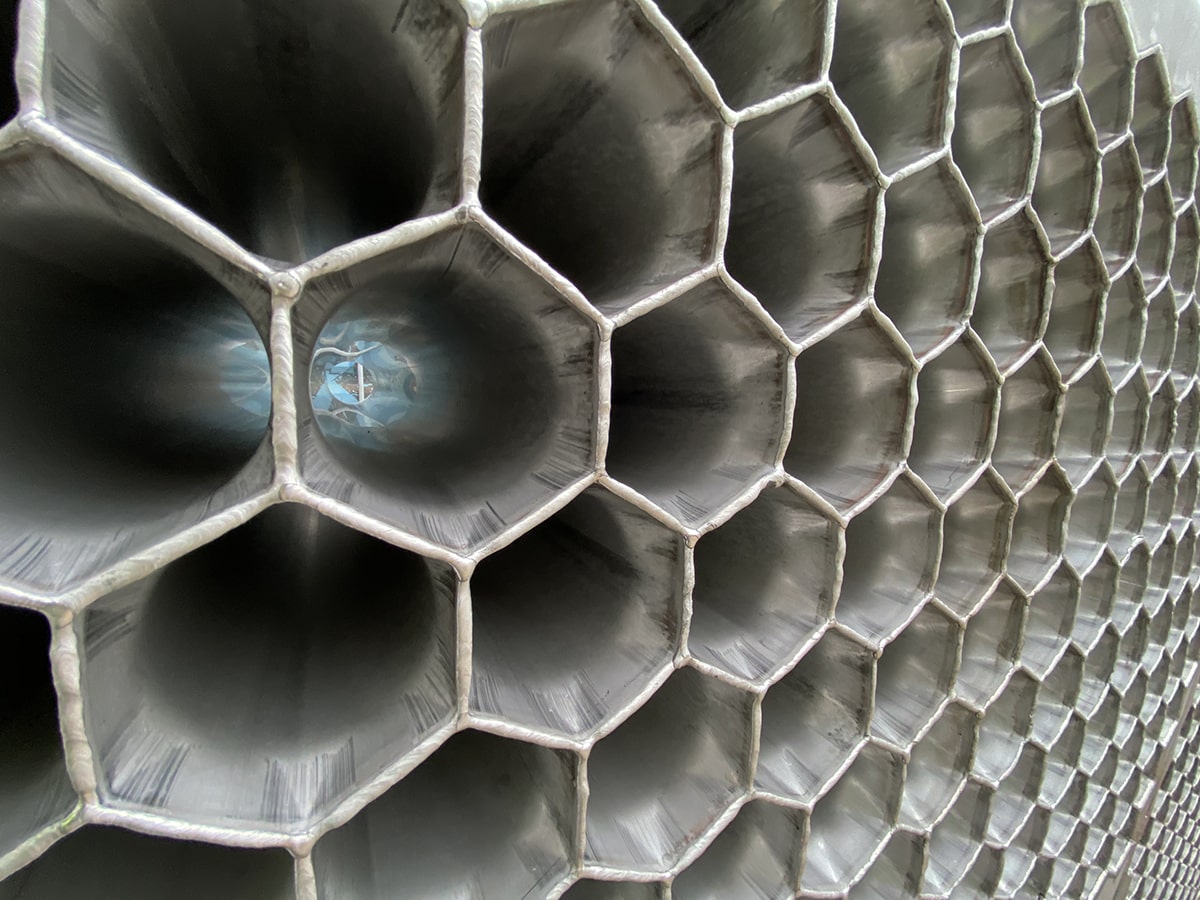

Why Honeycomb Chamber?

After 25-30 years of use, due to the widespread use of carbon steel for the production of vacuum pans until around 2009, it is necessary to replace the old heating chamber with a new one. Usually after such time, abrasions of the welds appear on the edges of the connecting pipes and, as a result, leaks between the steam chamber and the working space. Mostly the bottom of the chamber is damaged due to the circulation of massecuite from the bottom up.

Then the best choice is to insert a new honeycomb vacuum pan heating chamber made of stainless steel:

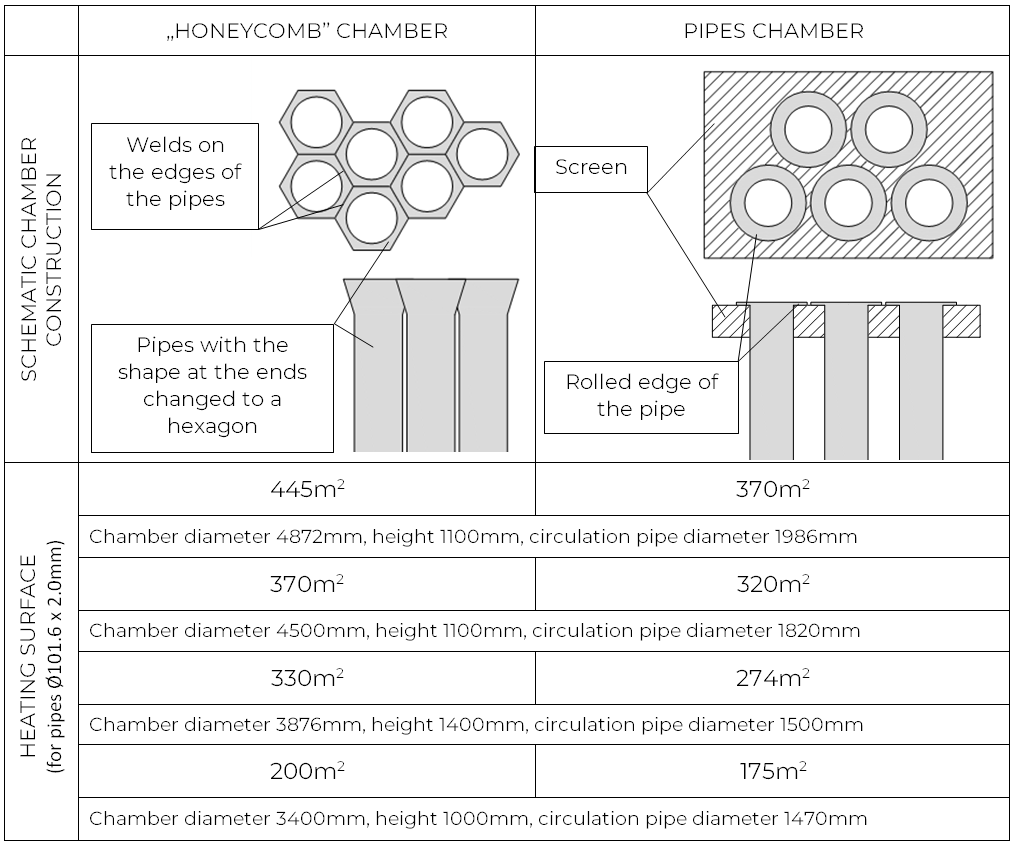

Up to 15% larger heating surface compared to the pipes chamber when using pipes of the same length. The design of the "honeycomb" chamber (no need for screen and no rolling of the pipe edges) allows for a more dense arrangement of the pipes

Replacing the pipes heating chambers in 6 vacuum pans with „honeycomb” chambers is an enlargement of the heating surface equal to the addition of 1 new vacuum pan with a pipies chamber

The possibility of shortening the pipes while maintaining the same heating surface as the pipes chamber - it is important for the proper circulation of massecuite

Lower purchase cost in relation to the pipes chamber in the case of a chamber with the same heating surface, because shorter pipes are used

Less weight of the” honeycomb” chamber in relation to the pipes chamber with the same length of pipes. In a situation where there is an old pipes chamber in the vacuum pan and we cannot increase the weight of the vacuum pan due to the strength of the building structure, the "honeycomb" chamber makes it possible to increase the heating surface by extending the pipes because it does not have a screen

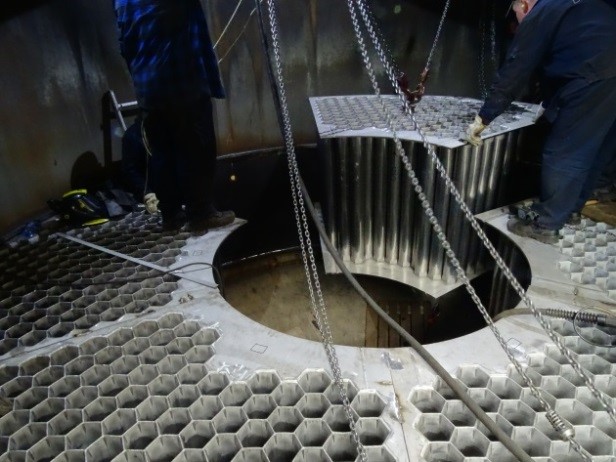

Our heating chambers are made of STAINLESS STEEL and are divided into segments, the so-called „cheeses”. The use of this solution offers many advantages:

Easy transport - avoiding the limitations of oversized transport

Possibility of transporting "cheeses" using transport lines in the sugar factory building - no need to remove the roof

Lifting segments with ordinary chain lifts

Minimal disturbance of the vacuum pan structure - cutting a hole in the vacuum pan shell

Easy assembly - no need to disassemble the steam and juice pipes and condensate collectors

References

To meet the expectationsof customers, in 2018 Polimex-Cekop-Moder started deliveries and assembly ofvacuum pan "honeycomb" type heating chambers. In the last 5 years, the company has delivered and installedthe technology in the following sugar factories:

dyfuzja wieżowa kruszwica

dyfuzja wieżowa kruszwica