Tower diffusion station Kruszwica

Finished erection of the diffusion tower and the cossete prescalder in the Kruszwica sugar factory

MORE

Crystalization NIKA/Znamienka 2016

Technical design and delivery of devices for station of crystalization and seed magma for sugar factories NIKA and Znamienka

MORE

Tower diffusion station Werbkowice

Finished erection of the diffusion tower and the cossete prescalder in the Werbkowice sugar factory

MORE

The official representative

PCM company is the official representative of many companies supplying devices for sugar industry in all the world

MORE

Sugar industry

We perform either single devices or machines, as well as complementary stations, modernizations.

POLIMEX CEKOP MODER SP. Z O.O.

ABOUT THE COMPANY

The origins of the POLIMEX-CEKOP-MODER company reach early 90’s of the last century, when dr Witold Łękawski, its former owner and a father of actual owner – Igor Łękawski, found the company MODER Ltd. In 1993 due to obtaining a very strong shareholder company POLIMEX CEKOP SA, the name of the company had been expanded to POLIMEX CEKOP MODER Ltd. At the end of 90’s years dr Witold Lekawski had bought out the shares from his partners and the company become an owned by the family Łękawski, a family which has connections with the sugar industry since the XIX’s century.

MORE >OUR SPECIALIZATION - SUGAR INDUSTRY

Our many year’s of experiences archived in domestic and abroad projects allow us to perform for the sugar industry projects of a single devices or machine delivery, as well as complementary stations, modernizations. Our specialization is:

- Expertise’s and conceptual designs of sugar factories:Modernization and expanding. Heat economy.

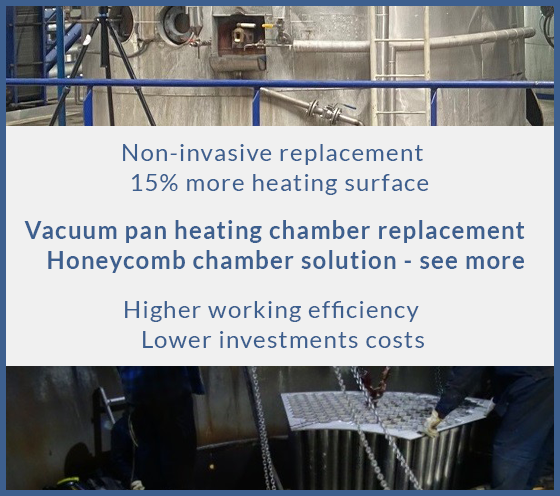

- Technical designs:Slicers and juice extraction. Pressing of the exhausted cossette. Drying of the exhausted cossette pulp. Storage, flotation/fluming and washing of beets. Lime kiln and stations of lime burning and slaking. Juice purification stations. Sulphation of water and juice. Juice filtration. Evaporation station and heat exchangers. Vacuum pan station. Seed magma. Centrifugation of massecuites. Sugar dryers. Stirrers/mixers of massecuite III. Heat chambers of vacuum pans. Barometric condensers. Automatic control (designs and deliveries). Processing of the data (software).

- Deliveries:Mash catchers. Bubblers of the carbonation gas. Liming devices. Carbonation devices. Decanters. DIASTAR filters. Falling film evaporators. Installations to sulphation of a water and a juice. Slurry pasta grinders. Stirrers/mixers to batch pans. Seed magma crystallizers. Stirrers/mixers of massecuite III. Heat chambers of vacuum pans. Water separators in barometric condensers.

- Computer systems of automatic control and production supervising: Heat economy

CONCEPTUAL DESIGNS

CONCEPTUAL DESIGNS

EXPERTISES AND AUDITS

EXPERTISES AND AUDITS

BALANCES

BALANCES

ANALYSIS & RECOMMENDATIONS

ANALYSIS & RECOMMENDATIONS

St. krystalizacji NIKA/Znam

St. krystalizacji NIKA/Znam

WER DIFFUSION KRUSZWICA

WER DIFFUSION KRUSZWICA